CUTTING PLATES

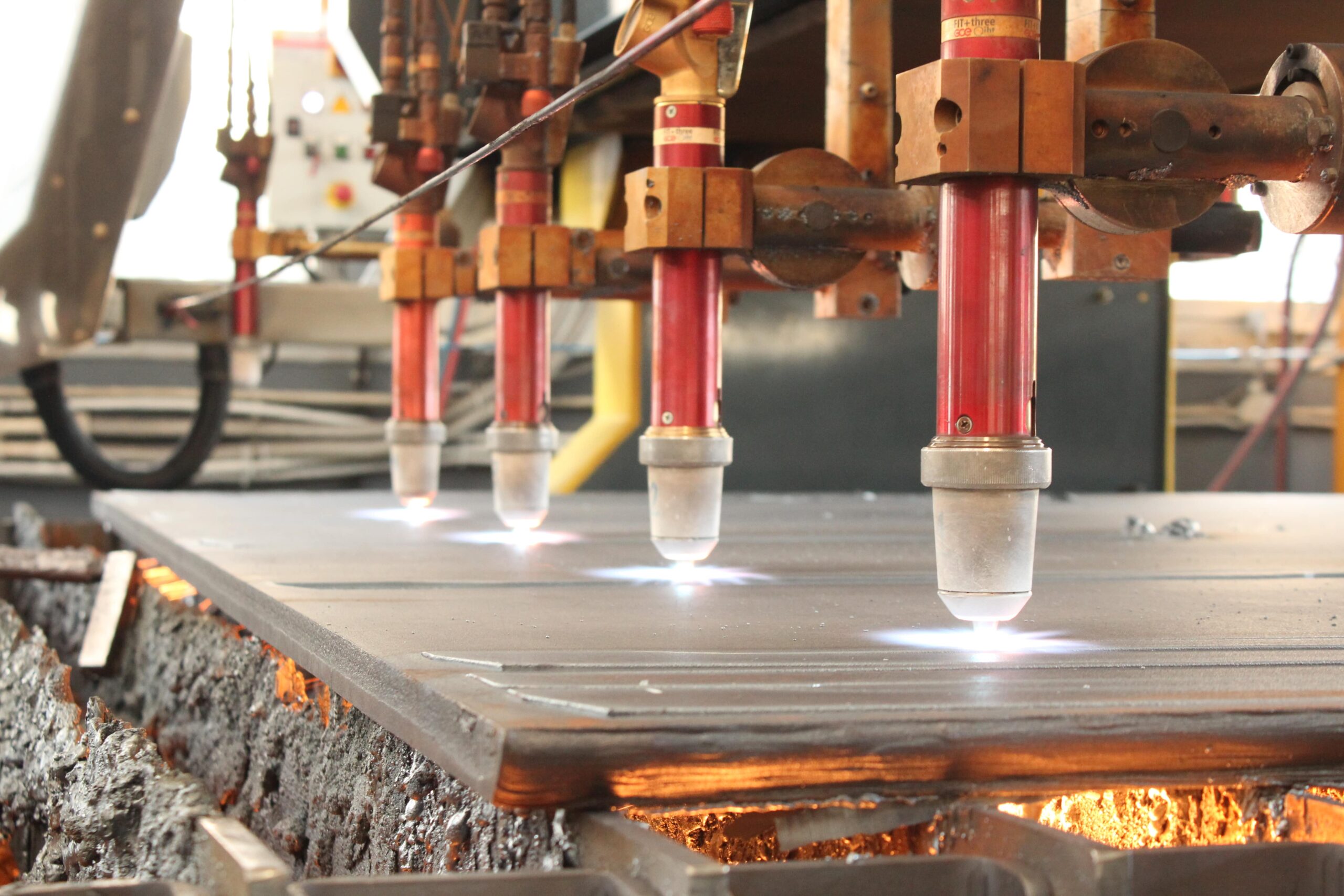

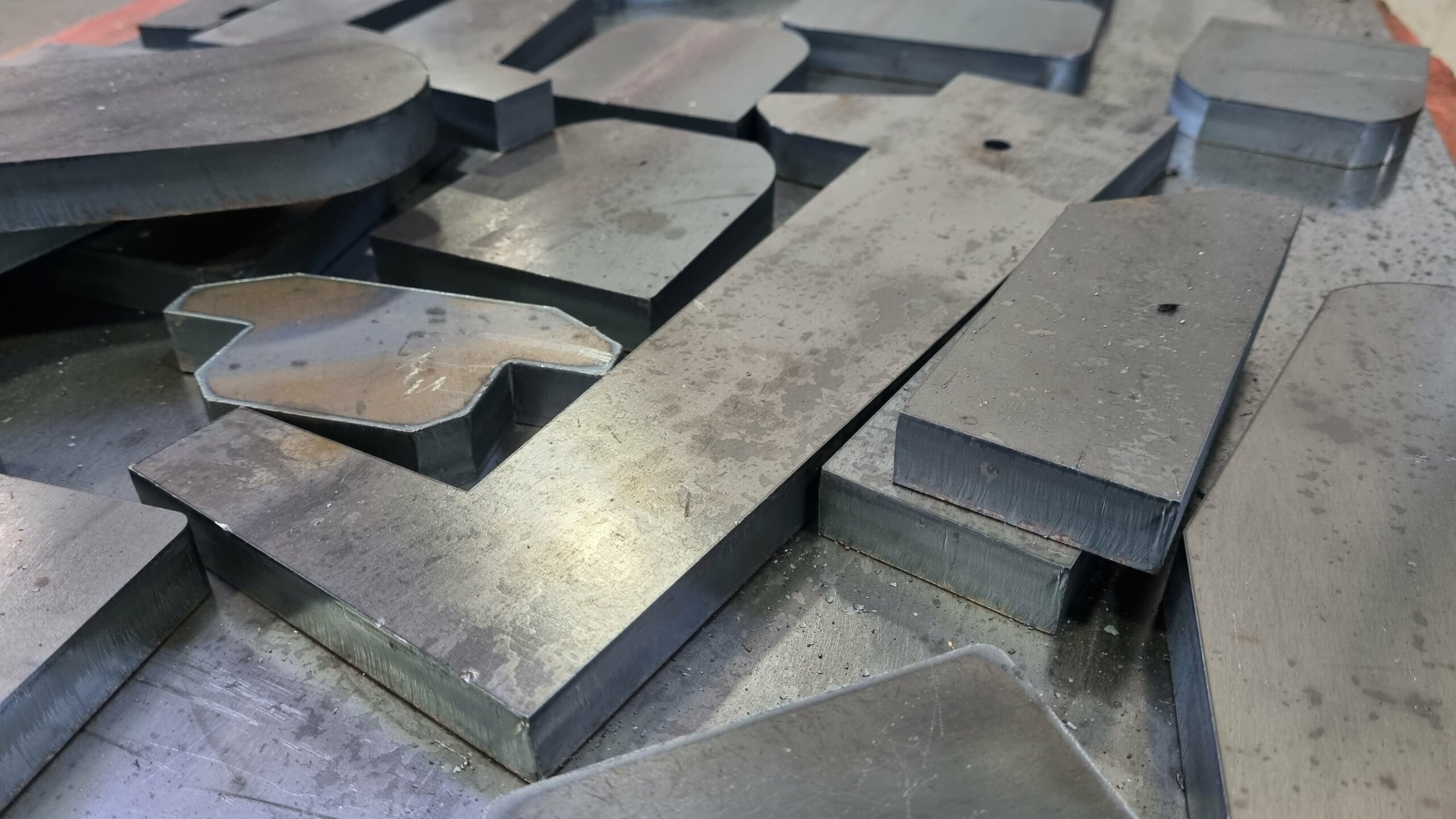

The integration of the IERP system and the available Laser, Plasma and Oxy-fuel technologies allow the cutting processes to be carried out in different thicknesses of material and in high quantities, following a flexible production plan.

The department is able to cut thicknesses from 0.5 mm up to 120 mm on dimensions of 2000×4000 mm with the Laser and 2500×12000 mm with the Plasma and/or Oxyfuel cutting machines.

STILFER mainly uses S355 construction steel in various types of resilience and S690QL1 hardened and tempered steels. Our stribg point is the traceability of the raw material, a fundamental requirement of ISO 9001 and ISO 3834, completely automated in all management phases.

MACHINES AND EQUIPMENT

- CY FIBER 15KW laser for sheet metal cutting from 2 to 15 mm with the following characteristics: X4100 axis, Y2050 axis, Z150 axis, load capacity 1600 kg; with automatic warehouse for 24-hour processing.

- Plasma SOITAAB LINEA TECH NOVA 40 useful cut 2,500×22,000 thicknesses from 2 to 60 mm, high definition cutting (square) and excellent surface finish, almost burr-free, extraction system. Automatic nesting with drawings in dxf or dwg format fully integrated with production management software;

- SOITAAB LINEA TECH NOVA Oxyfuel Pantograph, useful cut 2,500×12,000, thicknesses from 8 to 150 mm, extraction system, automatic nesting with drawings in dxf or dwg format, automatic suspensions; fully integrated with production management;

- COSTA MD5 machines for cleaning/deburring material up to a maximum of 100mm thick, 1100mm wide with vacuum system;

- Automatic band saw AMADA M PCSAW330 maximum cutting diameter 330mm, maximum cutting dimensions 330x330 mm