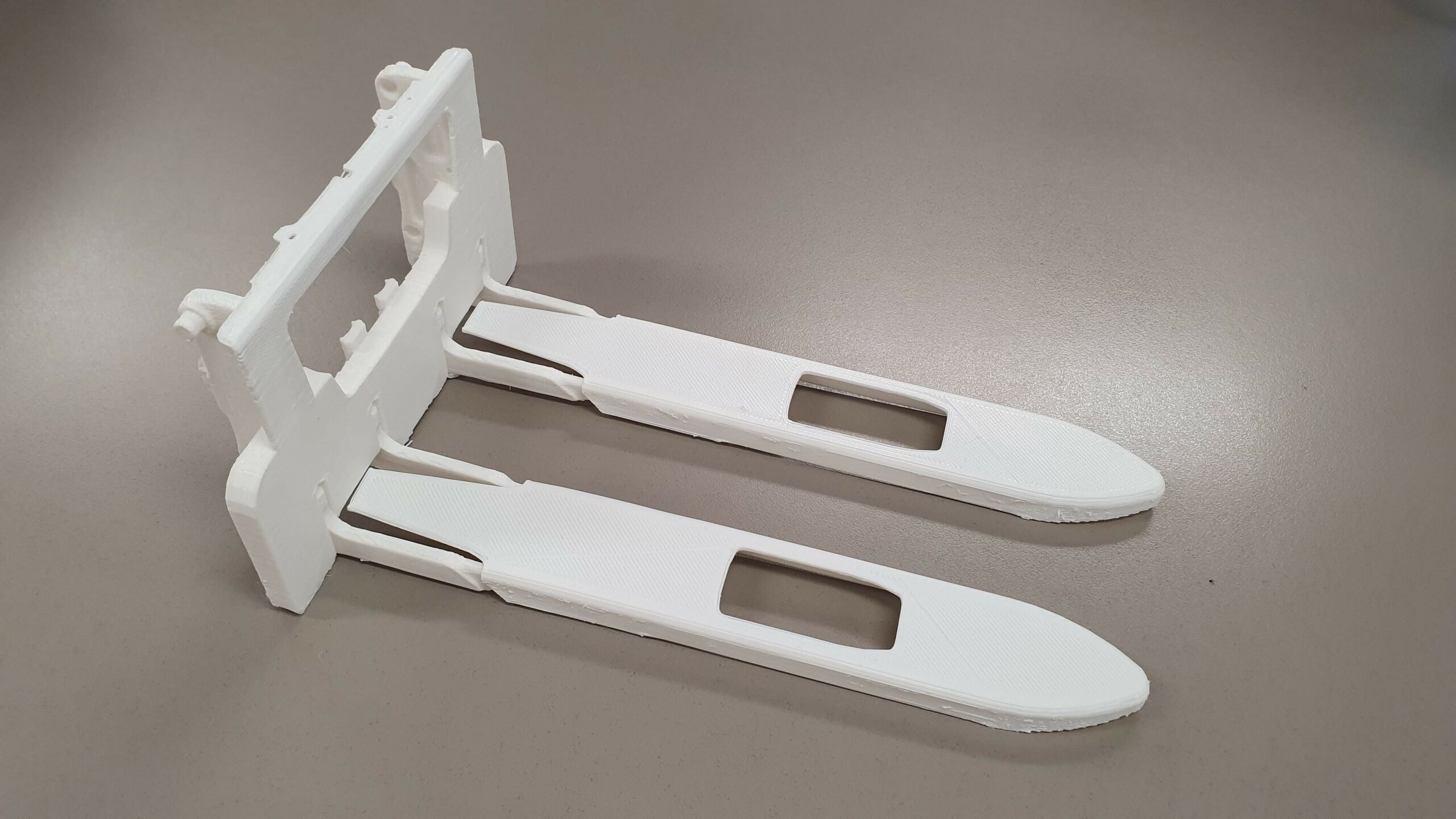

PRODUCT INDUSTRIALIZATION

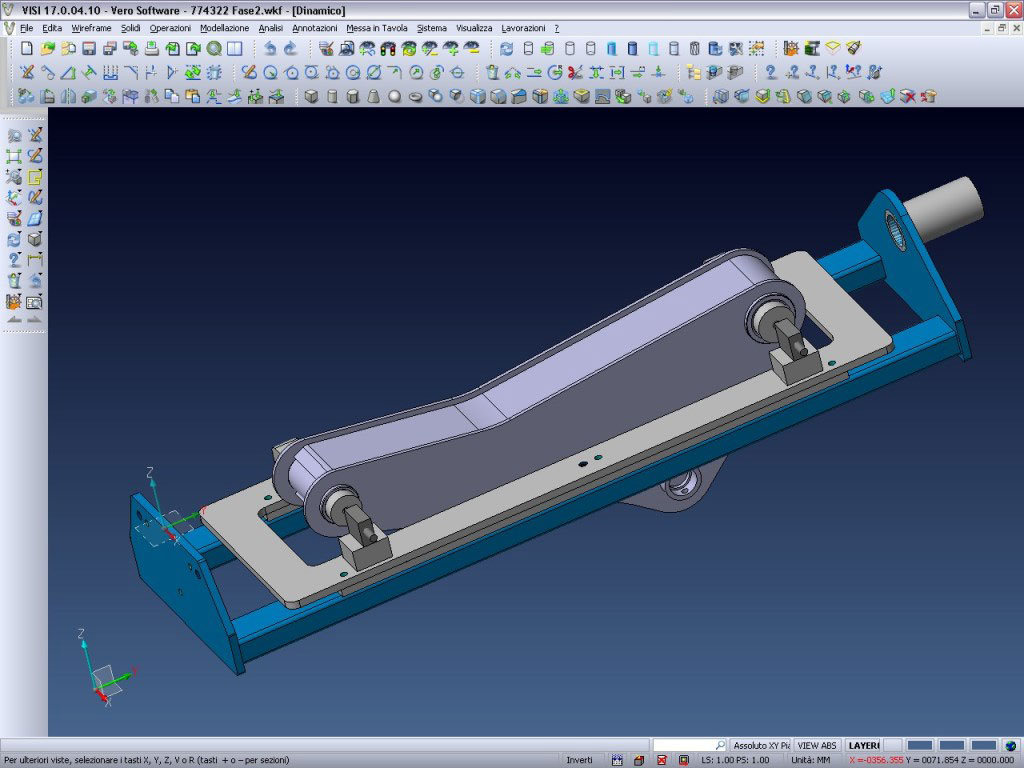

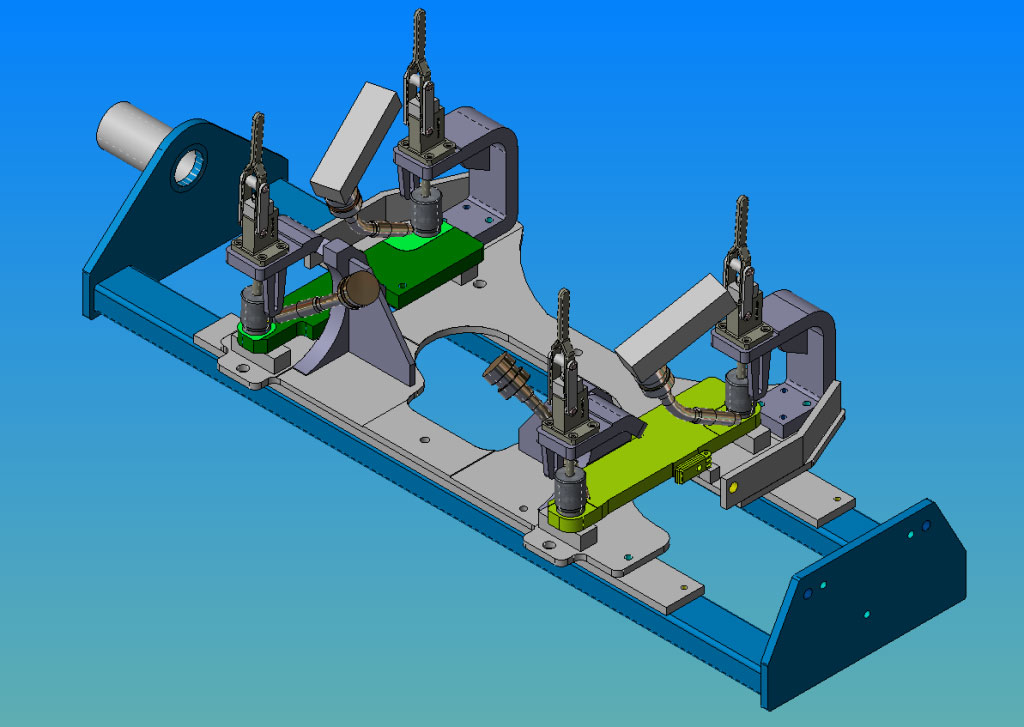

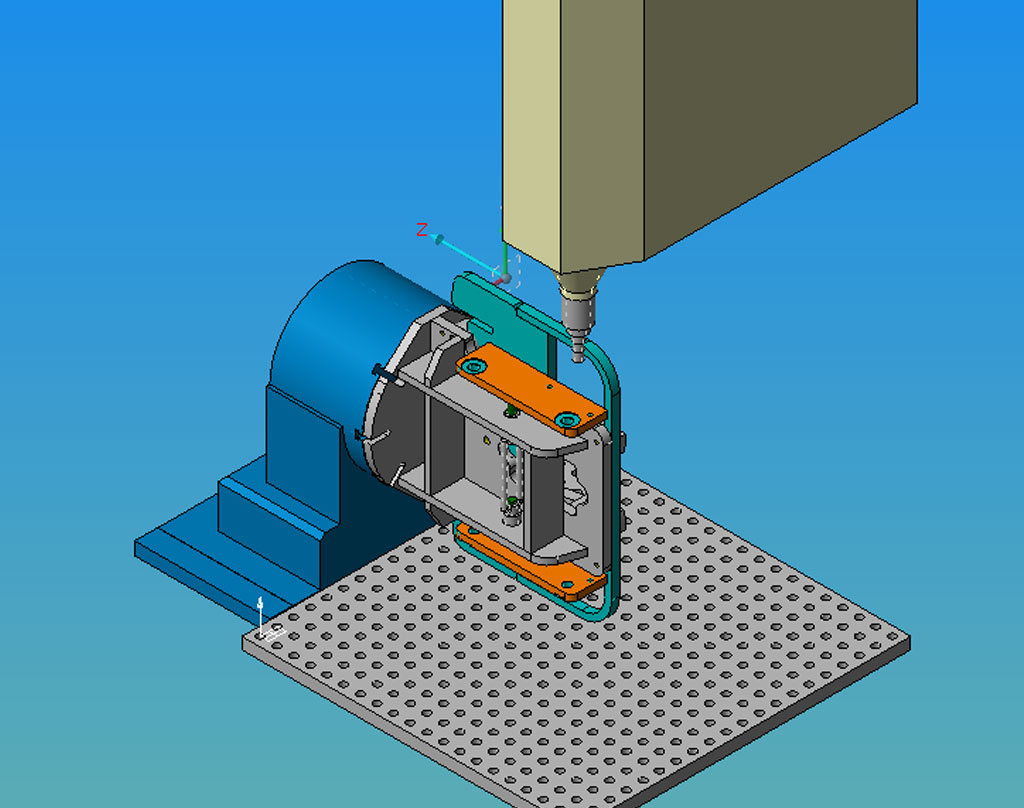

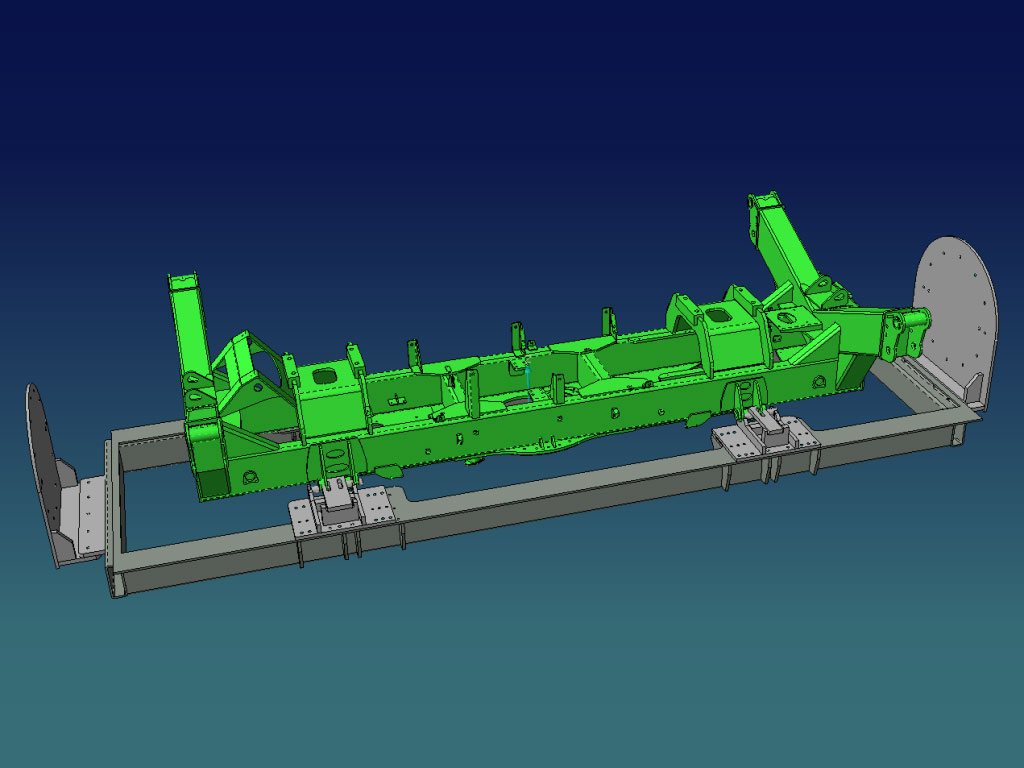

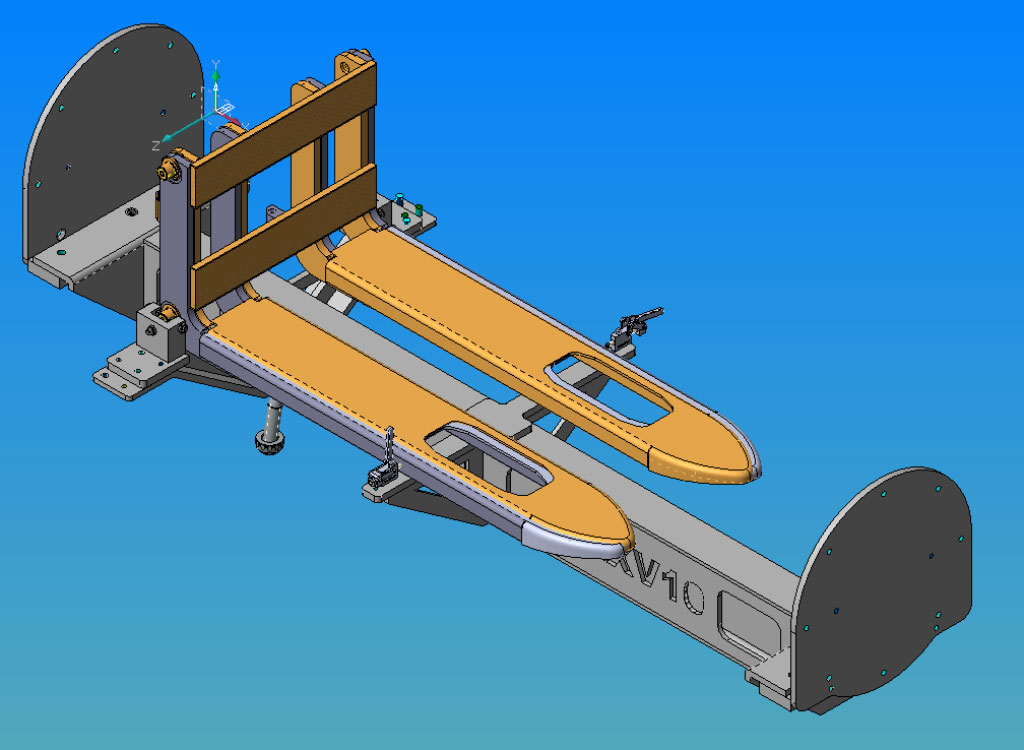

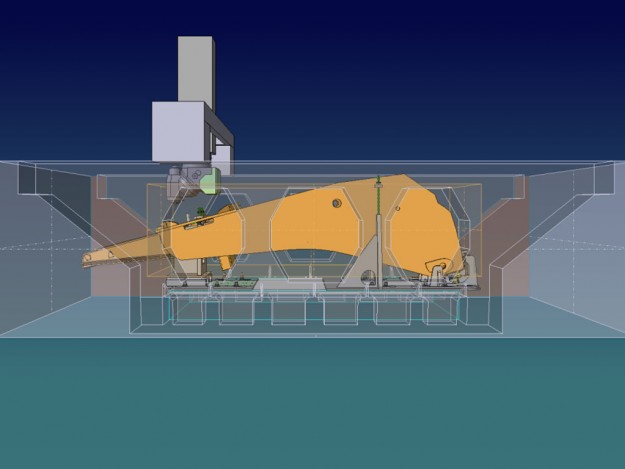

Metal carpentry is an activity that marries mechanical machining techniques with craftsmanship and expertise, because on the one hand, we make use of leading-edge computerized numerical control machinery, and on the other hand, we design and finish the products in such a way as to achieve high precision and correspondence to the design drawing.

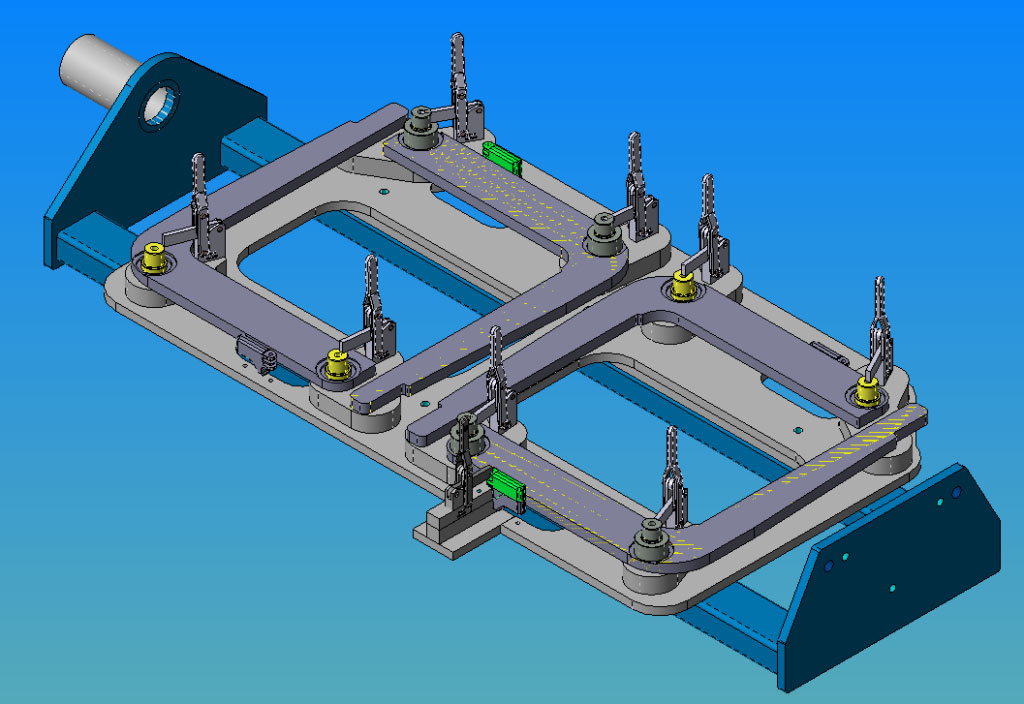

From the analysis of needs and objectives to the identification of the best solutions, the technical department of STILFER organizes all stages of the project to optimize time and costs, guaranteeing the quality standards defined by the customer.

The consolidated field experience gained in different sectors (automotive, earthmoving, telescopic, tire equipment, etc.), the wide range of skills and the proven and versatile working methods, allow to deal with every aspect of project development with great serenity.

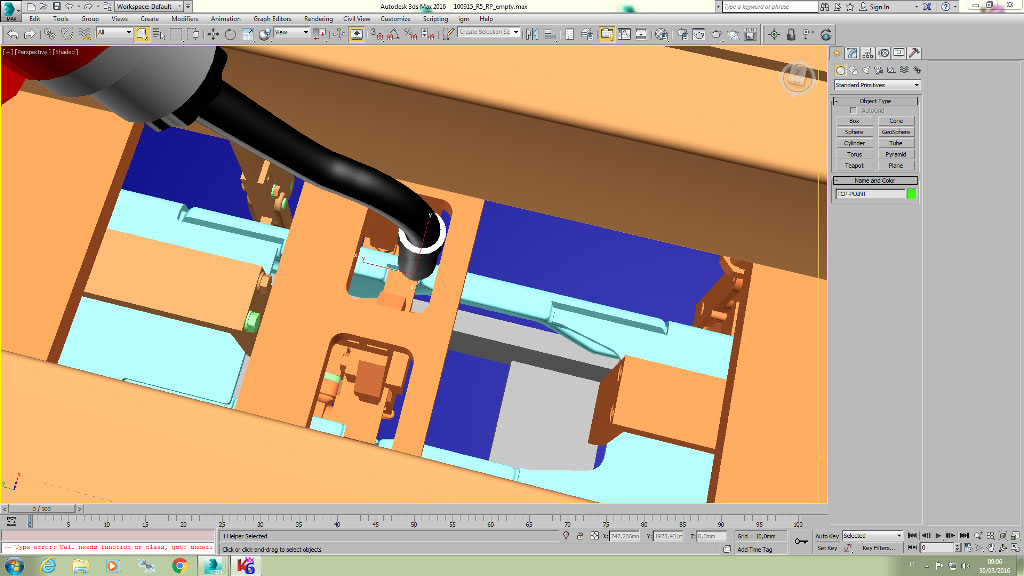

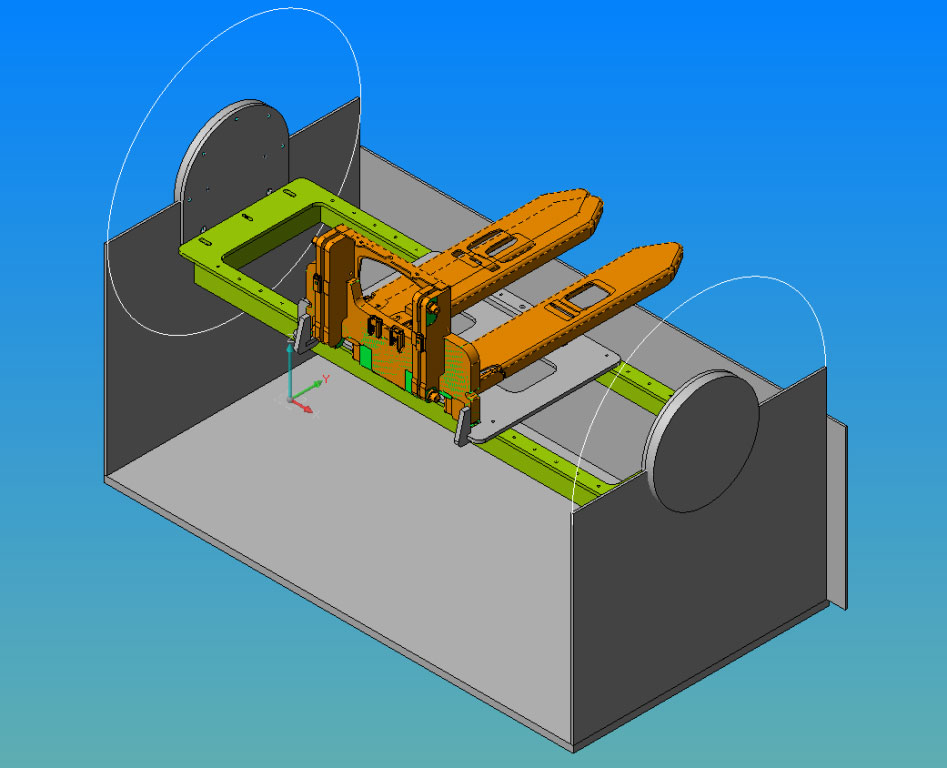

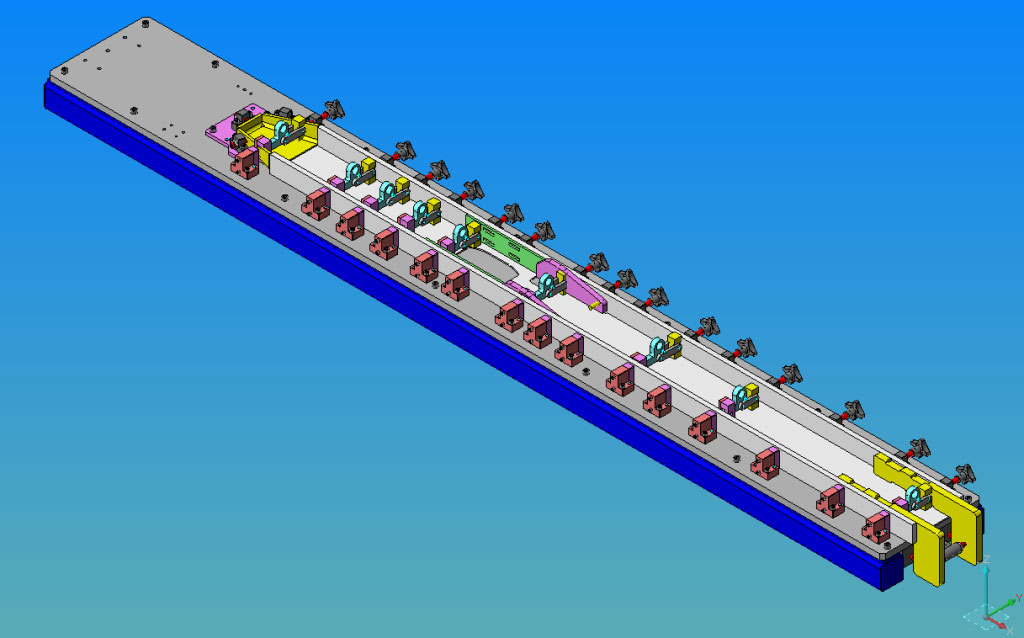

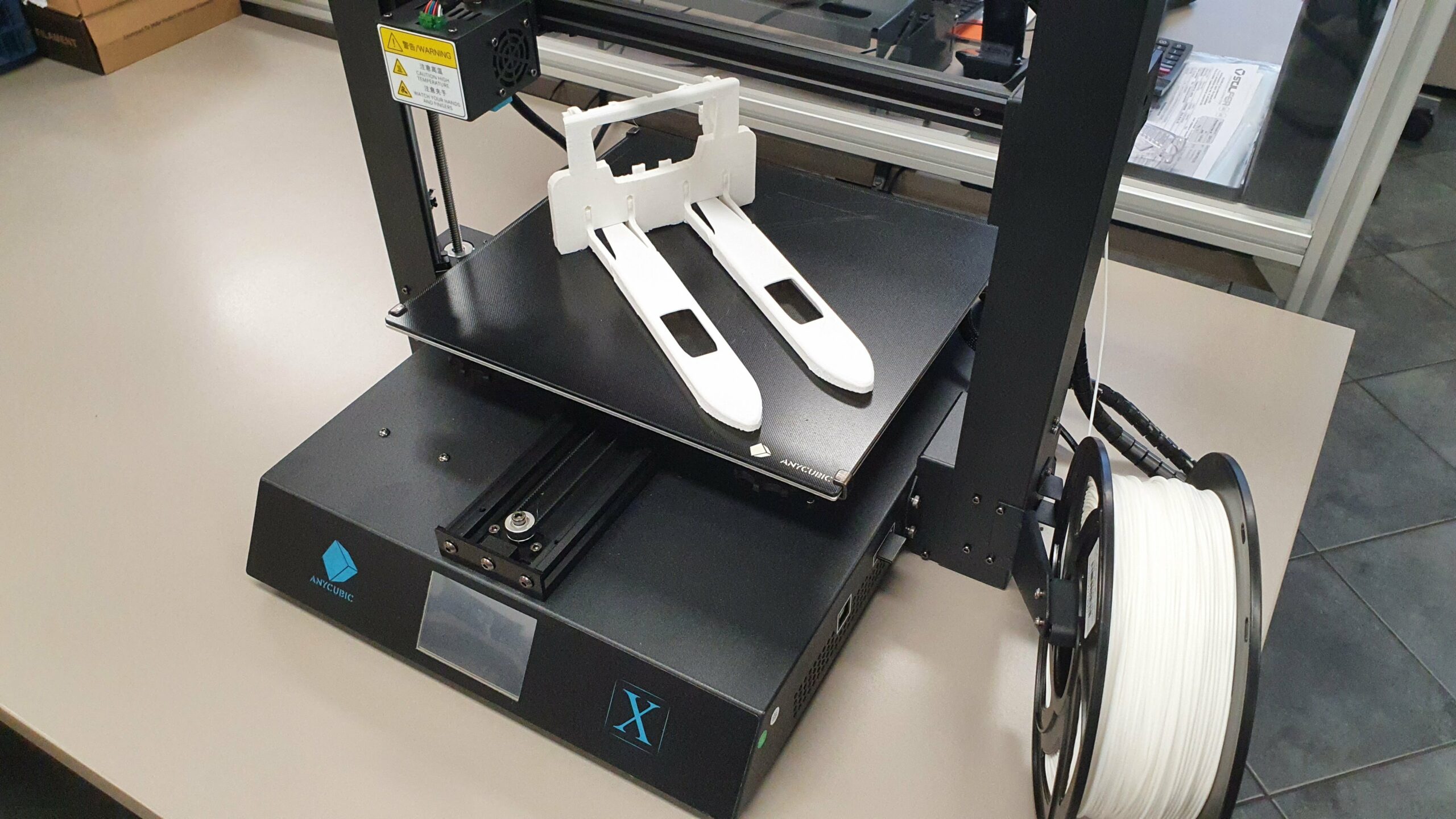

Thanks to an experienced technical staff capable of taking advantage of our state-of-the-art software, machinery and equipment, we are able to design and manufacture, depending on the type of product, the best manual, semiautomatic or automatic equipment, guaranteeing high quality standards in terms of time and cost of manufacture and in terms of the proper characteristics of the manufactured objects.

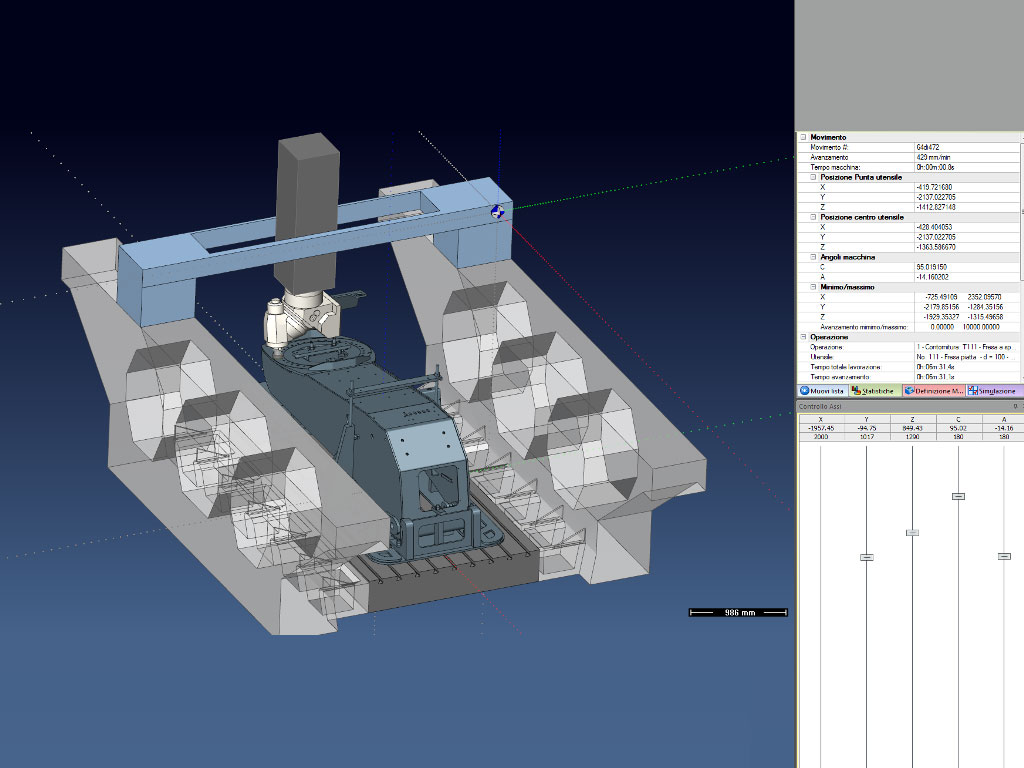

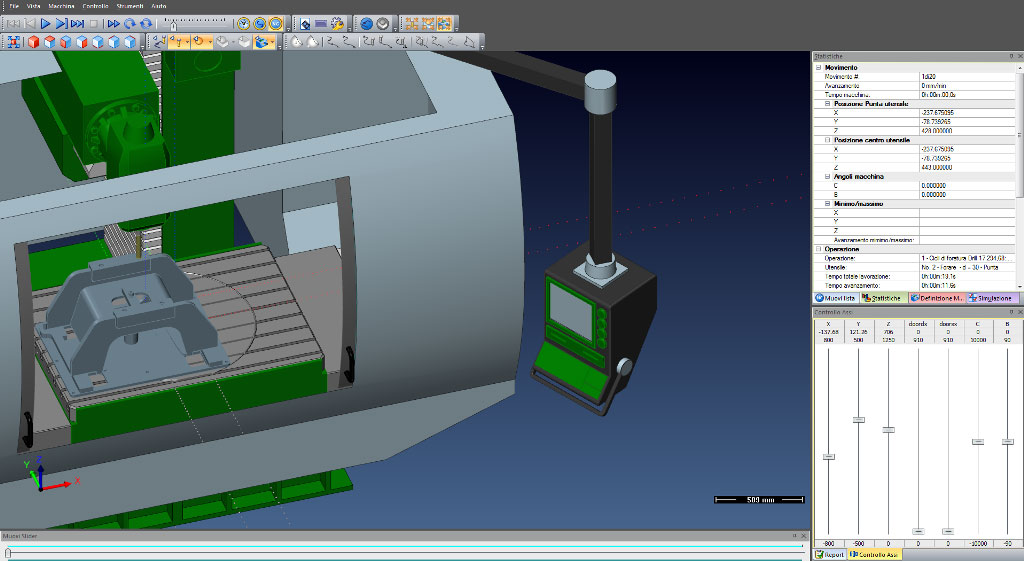

SOFTWARE AND TECHNOLOGY

- SolidWorks

- Autodesk Inventor

- Offline for remote welding robot programming

- Siemens Unigraphics NX

- CAD-CAM for machine tool programming

- CAPPS DMIS to define complete control over mathematical model by implementing easy and accurate CAD alignment