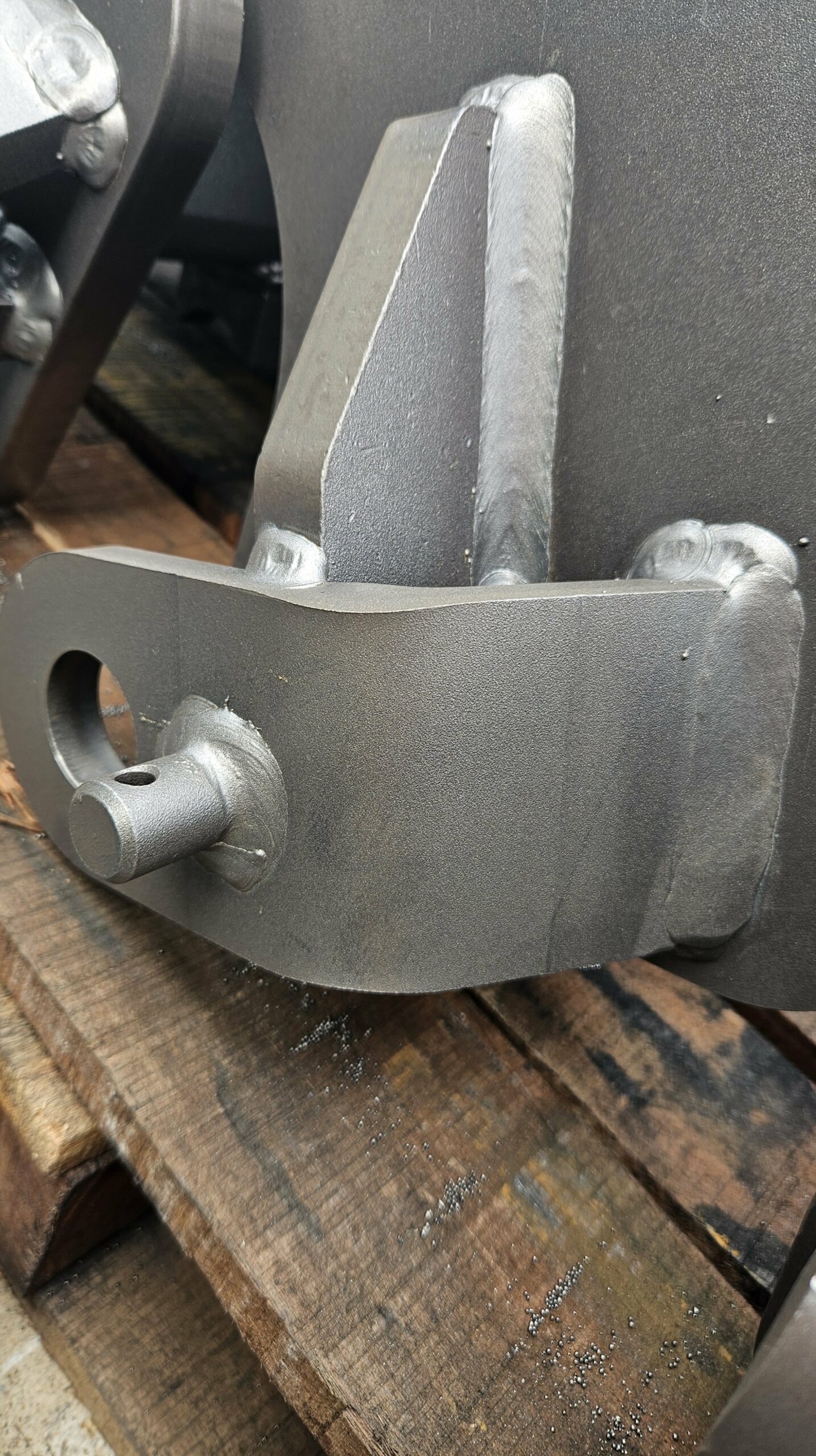

ROBOTIC WELDING

STILFER has 20 robotic stations equipped with single or double tables to work with dimensions of up to 7 meters and capacities of up to 5000 kg, operating in multiple shifts. We boast an automated process with attention to detail to guarantee maximum effectiveness and efficiency and, in particular, the repeatability of quality for each product created. Latest generation welders periodically checked with certified instruments, quality filler material and process control make welding carried out in STILFER an indispensable requirement for achieving excellence.

MACHINES AND EQUIPMENT

- IGM K5 RT330 robot suspended on 360° swivel support with 1500 long arm, continuous control rotation, R=750 double table orbital positioner, 500 kg capacity each, Fronius TPS5000 synergic generator;

- IGM K5 RT476 robot suspended on 360° swivel support with 1500 long arm, continuous control rotation, 180° rotary module positioner with 2 tables, 500 kg capacity, 2000 plate distance, 450 mm rotation radius, digital Fronius TPS5000 synergic generator;

- IGM KR6 Arc robot with 8 controlled axes, fixed to the ground, 180° rotary module positioner with 2 tables, 300 kg capacity, 1500 plate distance, 380 mm rotation radius, Fronius TPS5000 digital synergic generator;

- IGM RTE476 robot suspended on an 8 m longitudinal slide, 1.5 m transversal slide, 1.5 m vertical slide, a rotary table and idle tailstock, max. 4000 kg, useful distance 6 m Fronius TPSi500 digital synergic generator;

- IGM K5 RTI476-S 300 kg rotary tilting positioner, Fronius TPS5000 digital synergic generator;

- IGM K5 RT330 robot suspended on an 8 m longitudinal slide, 2.5 m transversal slide, 1.5 m vertical slide, a rotary table and idle tailstock, max. 6000 kg, useful distance 8 m, TWIN torch for welding simultaneously with two wires, Fronius TPS5000 synergic generator

- IGM K6 RTE497 robot with 6 axes and 1900 mm working radius, manipulator with turntable of max 1,000 kg Fronius TPS500i digital inverter generator (coupled with RTE497-S robot);

- IGM K6 RTE497-S robot with 7 axes and 1900 mm working radius, manipulator with turntable of max 1,000 kg, digital Fronius TPS500i inverter generator (coupled with RTE497 robot).

- IGM K6 RTE497-S robot with 7 axes and 1900 mm working radius, manipulator with turntable of max 2,000 kg, digital Fronius TPS500i inverter generator

- ABB IRB2600 robot with 6 axes and 1900 mm working radius, with double station orbital positioner of max 750 kg, Fronius TPS500i digital inverter generator